Spreading models like Openai’s Dall-E are increasingly useful in helping to brainstorm new designs. Humans can encourage these systems to generate images, create videos, improve blueprints, and return ideas they have never thought of before.

But did you know that generative artificial intelligence (Genai) models are also making progress in creating work robots? A recent diffusion-based approach has generated structures and systems that control them from scratch. With or without user input, these models can create new designs and evaluate them in simulations before they are manufactured.

A new approach from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) applies this generative know-how to improve human robot design. Users can draft a 3D model of the robot and provide dimensions in advance, specifying the part where the spreading model wants to be changed. Genai then brainstorms the best shapes for these areas and tests the idea in a simulation. Once the system finds the right design, it can be used to store and create a working real-world robot using a 3D printer without the need for additional adjustments.

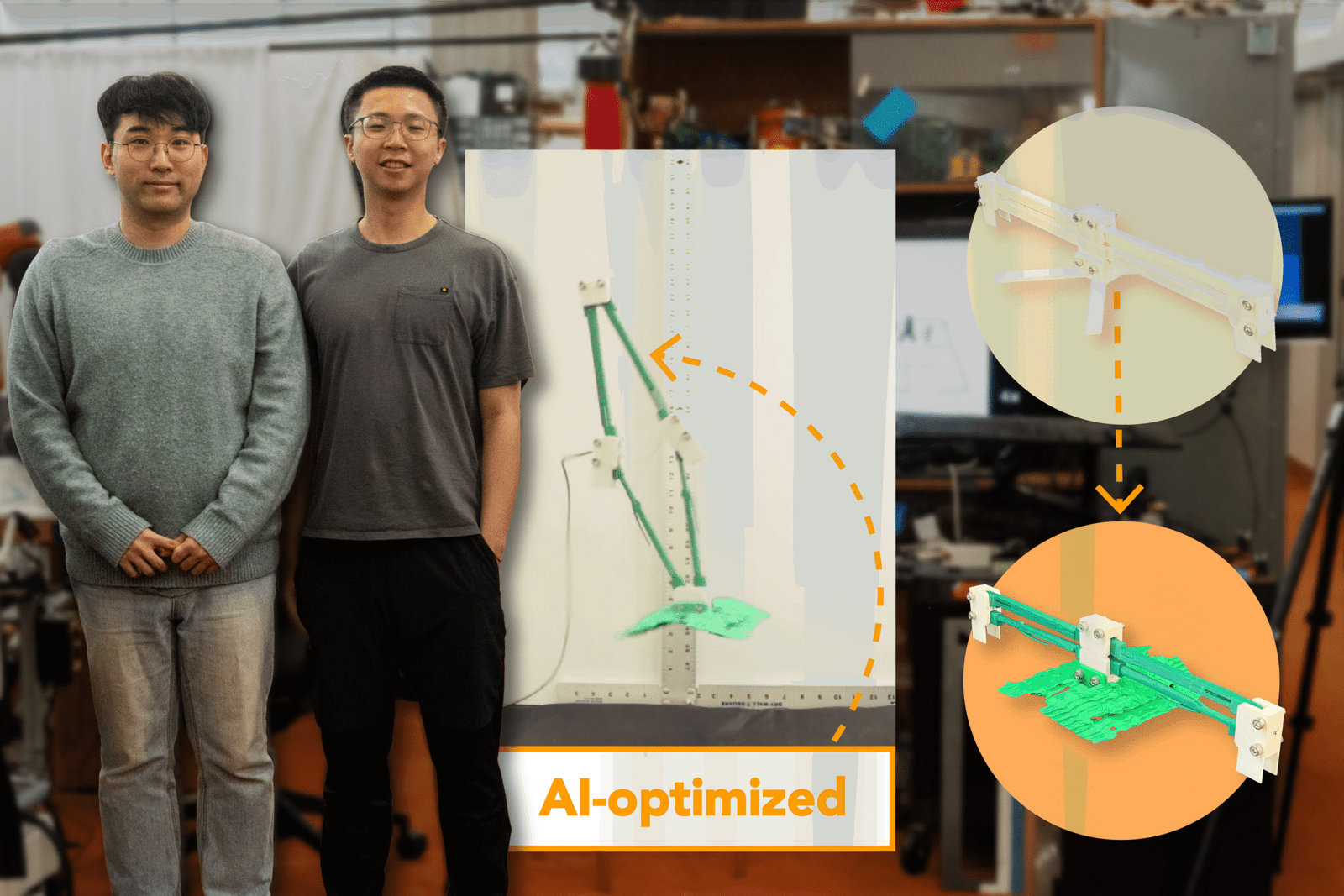

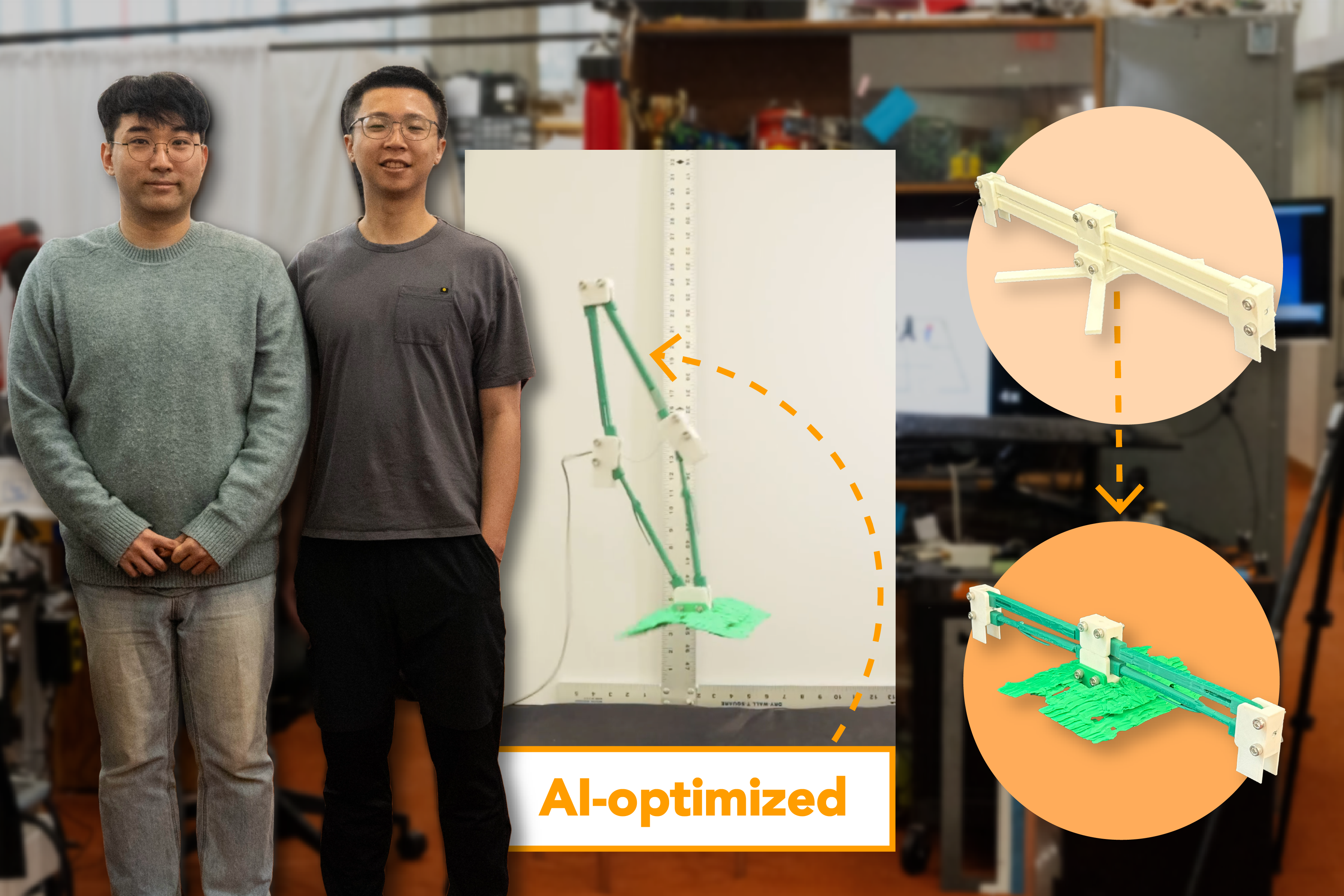

Researchers used this approach to create robots that are about 2 feet or 41% more expensive than similar machines they created themselves. The machine looks almost the same. Both are made from a type of plastic called polylactic acid, which initially look flat, but when pulled on the cord with the motor mounted it becomes diamond-shaped. So, what did AI do differently?

If you look closely, you can see that the AI-generated linkage is curved and resembles a thick drumstick (used by instrumental drummers), but the standard robot connections are straight and rectangular.

Better lump

Researchers began improving the jump robot by sampling 500 potential designs using initial embedding vectors. This is a numerical representation that captures high-level capabilities that guide the design generated by AI models. From these, they selected the top 12 options based on the performance of the simulation and used them to optimize the embedded vectors.

This process was repeated five times to gradually guide the AI model and generate a better design. The resulting design was similar to BLOBs, so researchers urged the system to scale the draft to fit the 3D model. They then created the shape and discovered that the robot’s jumping ability had actually improved.

According to co-lead author Csail Postdoc Byungchul Kim, the benefit of using a diffusion model for this task is that you can find unconventional solutions to refine your robots.

“We wanted the machine to be taller, so we thought we could make it lighter by allowing links to make the parts as thin as possible,” Kim says. “However, such thin structures can easily break just by using 3D printed materials. The diffusion model came up with a better idea by proposing a unique shape that allows the robot to store more energy before jumping up and down, without thinning the link.

The team then appointed a system that drafted optimized feet to ensure that they landed safely. They repeated the optimization process and ultimately chose the best performance design to connect to the bottom of the machine. Kim and his colleagues found that AI-designed machines were much less frequent than the baseline, falling into 84% improvement adjustments.

It suggests that the ability of the diffusion model to upgrade robot jump and landing skills may help to enhance the way other machines are designed. For example, companies working on manufacturing and domestic robots can use similar approaches to improve their prototypes, which usually saves engineers time by repeating these changes.

The balance behind the bounce

To create a robot that can jump high and land stably, researchers have realized that both goals need to be balanced. They represented both jump height and landing success rate as numerical data, and then trained the system to find sweet spots between embedded vectors that help to construct the optimal 3D structure.

Researchers point out that this AI-assisted robot is superior to human-designed counterparts, but could soon reach even greater new heights. This iteration involves the use of materials compatible with 3D printers, but future versions will jump even higher with lighter materials.

Co-starring author and student Tsun-Hsuan “Johnson” Wang, MIT CSAIL PhD, says the project is a jump-off point for new robotics designs that can be supported by generative AI.

“We want to fork into a more flexible goal,” Wang says. “Imagine using natural language to derive a diffusion model, drafting a robot that can pick up a mug, or manipulating an electric drill.”

Kim says the diffusion model can also generate joints and make it an idea about how parts connect. The team is also investigating the possibility that the machine will jump and add a motor to control the direction that will likely improve the stability of the landing.

Researchers’ research was supported in part by the National Science Foundation’s Emerging Frontier for Research and Innovation Programs, Men’s in Research Technology, Singapore Mit Alliance for Manus and Masina Programs, and the Gwangju Institute of Science and Technology (GIST)-CSAIL collaboration. They presented their works at the 2025 international conference on robotics and automation.