Cell therapy represents a promising new frontier in medicine, particularly in the treatment of diseases such as cancer, inflammatory diseases and chronic degenerative disorders. However, a major challenge in CTP production is to quickly and effectively ensure that cells are not free from contamination before being administered to patients.

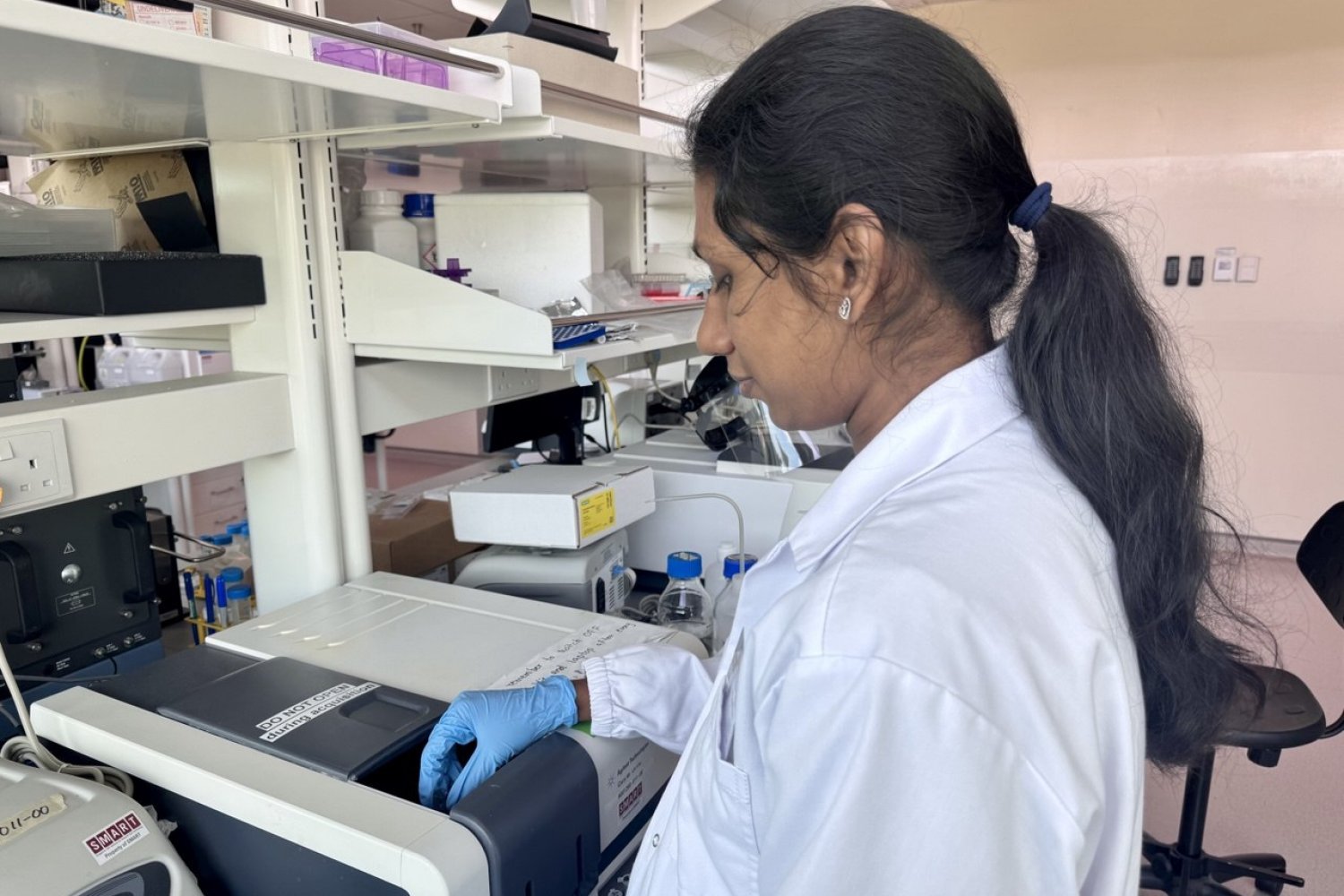

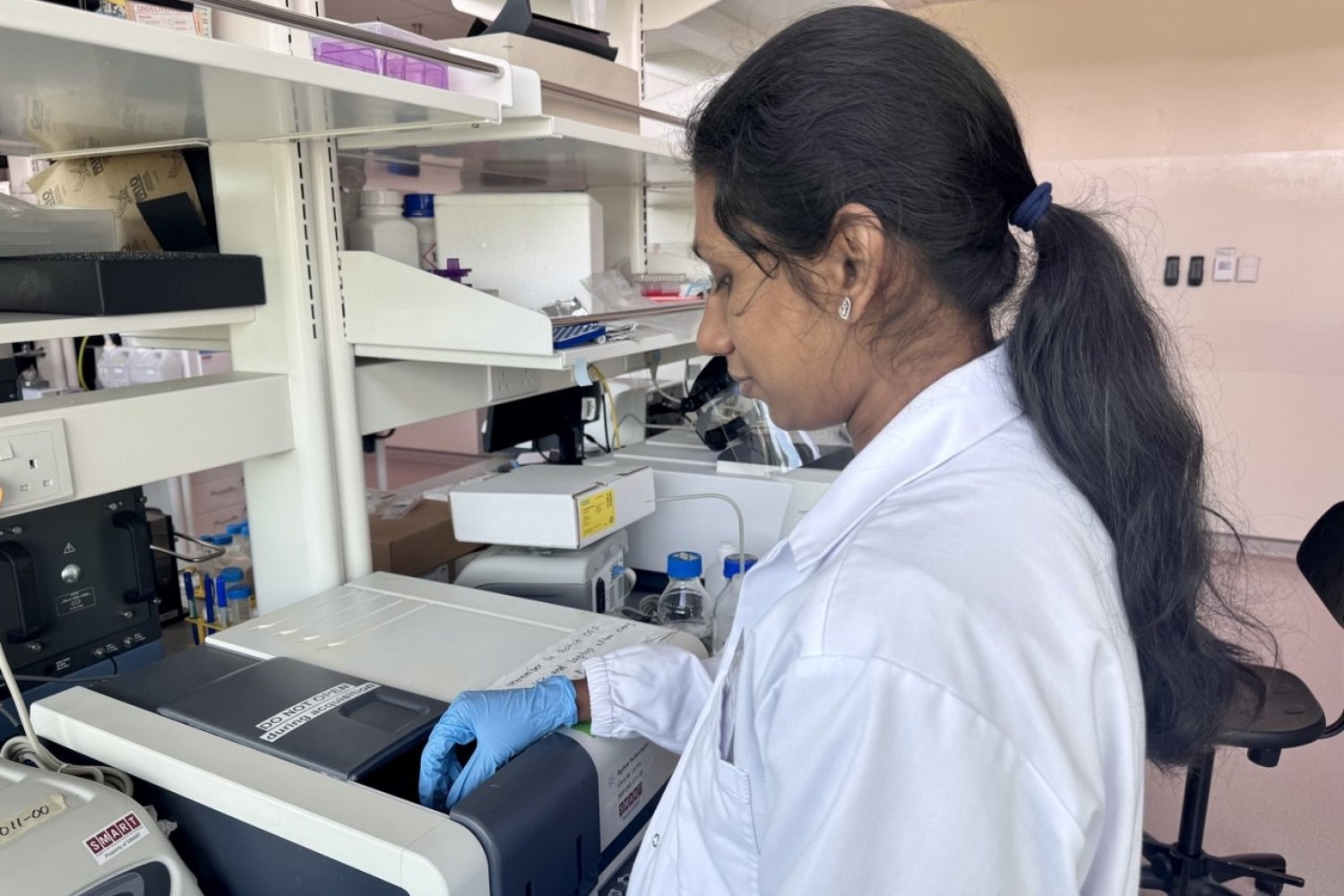

Existing fertility testing methods based on microbiological methods are labor intensive and require up to 14 days to detect contamination, and can have a negative impact on critically ill patients who require immediate treatment. Advanced techniques such as rapid microbiological methods (RMM) can shorten the testing period to seven days, but require complex processes such as cell extraction and growth enrichment media, relying heavily on skilled workers for procedures such as sample extraction, measurement, and analysis. This creates an urgent need for new ways to deliver faster results without compromising CTP quality, meeting patient use timelines and using simple workflows that do not require additional preparation.

This method offers greater advantages over both traditional sterility testing and RMM. This is because staining of cells eliminates the need to identify labeled organisms, avoids the invasive process of cell extraction, and results within 30 minutes. Provides an intuitive and rapid “yes/no” contamination assessment and facilitates automation of cell culture sampling with a simple workflow. Furthermore, the developed method does not require specialized equipment and reduces costs.

“This rapid, label-free method is designed as a preliminary step in the CTP manufacturing process as a form of continuous safety testing of the CTP manufacturing process. This allows users to detect contamination early and implement the use of RMMS only if possible contamination is detected. The first author of the paper.

“Traditionally, cell therapy manufacturing is labor intensive and is affected by operator variation. We want to streamline the production of cell therapy and reduce the risk of contamination by introducing automation and machine learning. Specifically, this method supports automated cell culture sampling on designated Internet to check for contamination. It was detected early on,” says Rajeev Ram, professor of electrical engineering and computer science at MIT, the lead investigator at Smart Camp.

Future research will focus on expanding the application of methods that include a broader range of microbial contaminants, particularly the current good manufacturing practice environment and representatives of previously identified CTP contaminants. Furthermore, the robustness of the model can be tested with more cell types other than MSCs. Beyond the manufacture of cell therapy, this method can also be applied to the food and beverage industry as part of microbial quality control testing to ensure that food safety standards are met.